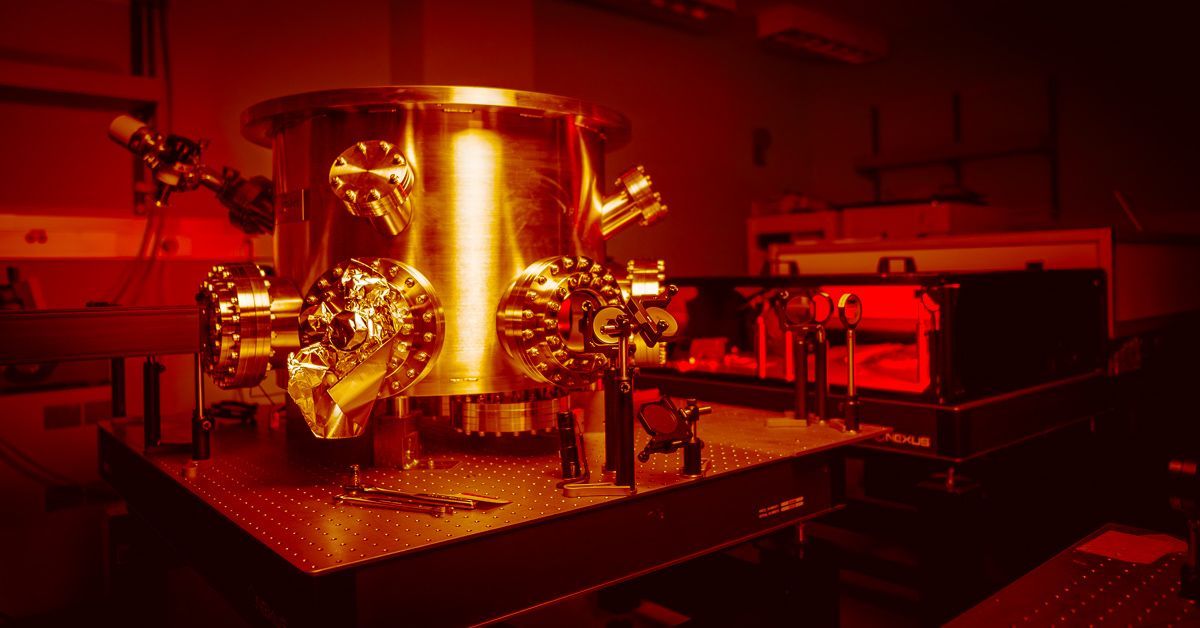

An experimental chamber that will be used by UC San Diego as part of the TINEX project. (Photo: David Baillot/UC San Diego Jacobs School of Engineering)

The University of California–San Diego has joined a new research collaborative focused on overcoming critical obstacles in developing and scaling up inertial fusion power plants. Led by San Diego-based General Atomics, the group was one of six research teams that were collectively awarded $107 million in January by the Department of Energy as part of the Fusion Innovative Research Engine (FIRE) Collaboratives.

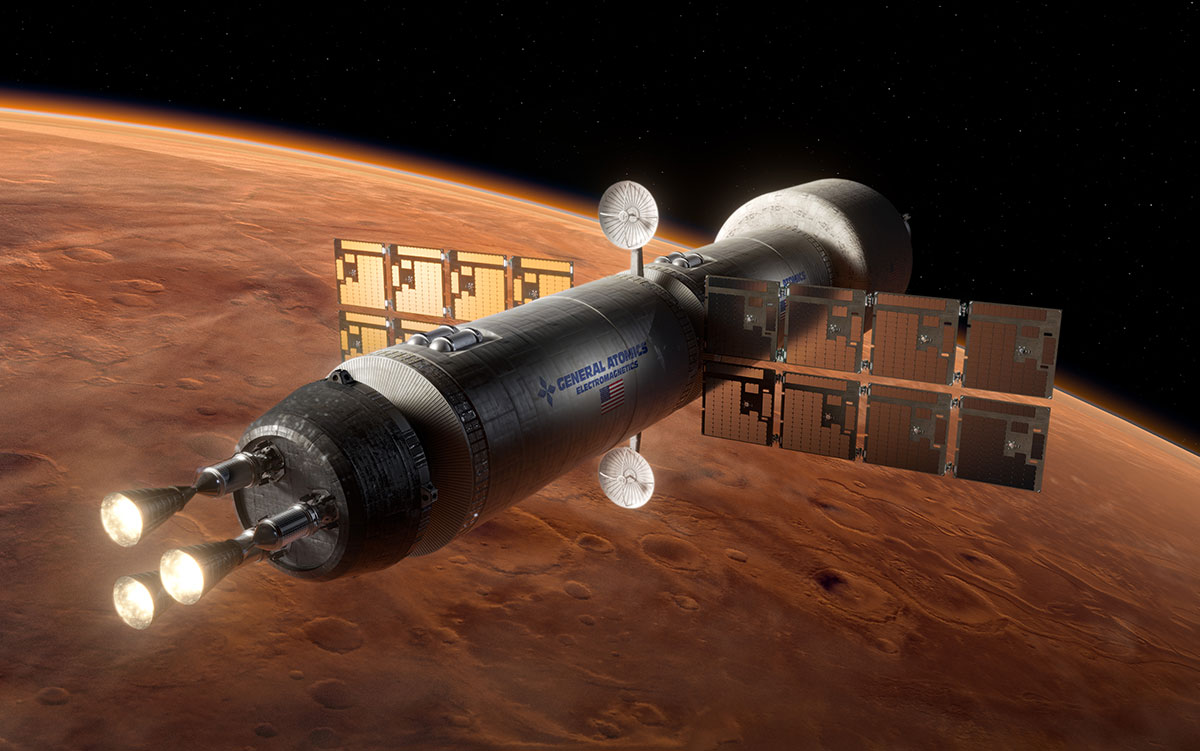

(Image: General Atomics Electromagnetic Systems)

General Atomics Electromagnetic Systems (GA-EMS) announced last week that unfueled test rods featuring the company’s SiGA fuel cladding—made of a silicon carbide composite material—successfully survived 120 days of irradiation in the Advanced Test Reactor (ATR) at Idaho National Laboratory.

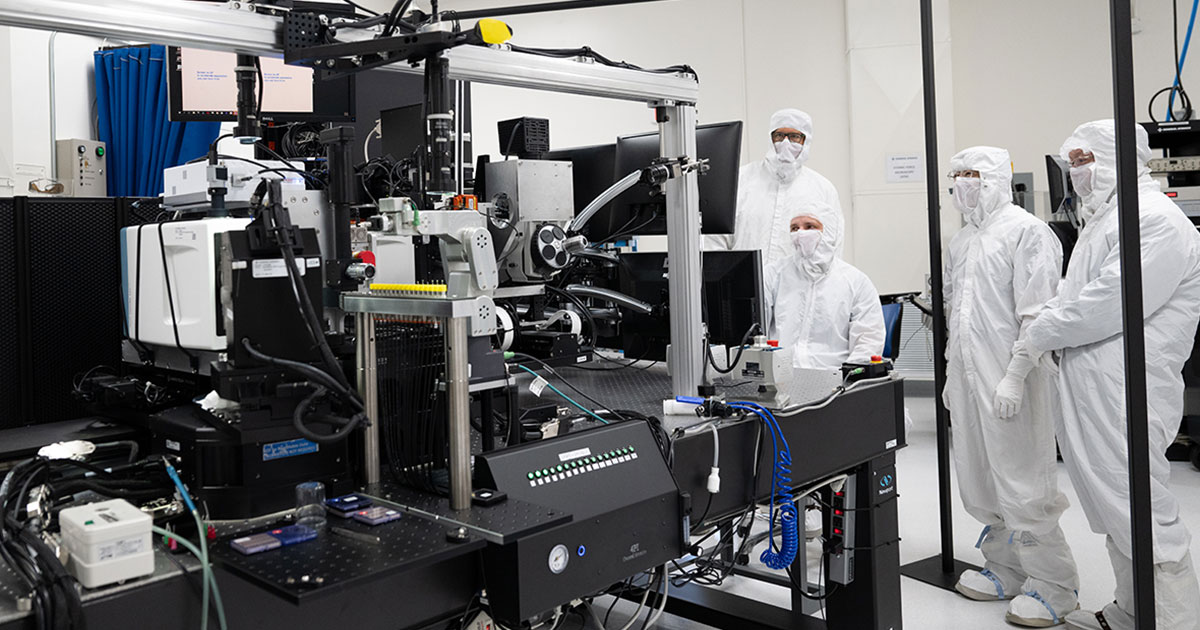

Members of the Metrology Research and Development team working with the 4Pi system in a clean room at GA headquarters. (Photo: General Atomics)

The National Ignition Facility (NIF) at Lawrence Livermore National Laboratory has achieved fusion ignition at least five times, each time by directing its 192 high-powered lasers on a capsule containing a tiny, 2-millimeter target filled with hydrogen fuel. Not every shot achieves ignition, however. Tiny imperfections in the targets can mean fizzle, not fusion. But each of the targets used in successful experiments to date have something in common: they were characterized and selected by the 4Pi Integrated Metrology System, a new measurement system developed by General Atomics. Now, the team behind that system is being recognized.

GA announced last week that its Metrology Research and Development team had won the 2024 "Team of the Year" R&D 100 Professional Award from R&D World. The magazine that each year announces the R&D 100 awards that have been dubbed the “Oscars of Innovation” also selects just one “Team of the Year” and announces that award together with four other professional awards.

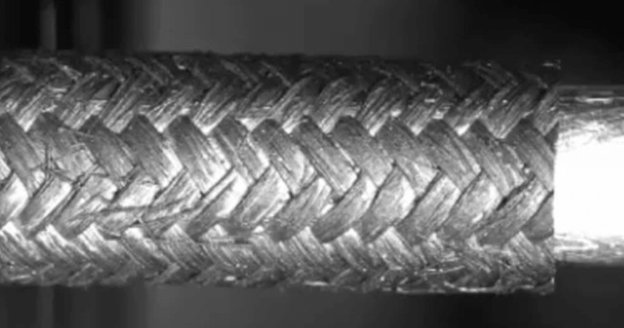

SiGA woven silicon carbide nuclear fuel cladding. (Photo: DOE)

Because of its hardness and its hardiness in the face of high temperatures, silicon carbide has been used for industrial purposes for decades. It has proven its worth as a key component of tiny TRISO fuel particles. But SiC has a weakness—in its pure form it is too brittle for use in structural components, such as 12-foot-long light water reactor fuel cladding tubes.

The DIII-D Superfacility team. (Photo: General Atomics)

Researchers at the DIII-D National Fusion Facility, the National Energy Research Scientific Computing Center (NERSC) at Lawrence Berkeley National Laboratory (LBNL), and the Energy Sciences Network (ESnet) are teaming up to make the high-performance computing (HPC) powers of NERSC available to DIII-D researchers through ESnet—a high-speed data network. Their collaboration, described in a May 29 news release, in effect boosts the computing power behind DIII-D’s diagnostic tools to make more data from fusion experiments available to researchers at DIII-D in San Diego and to the global fusion research community.

An engineer adjusts mirrors while installing new diagnostic equipment inside the DIII-D tokamak. (Photo: General Atomics)

The DIII-D National Fusion Facility is starting up after an eight-month experimental hiatus, equipped with new and improved plasma control and diagnostic systems. The upgrades will help researchers from around the nation and the world resolve key physics questions to bridge the gap between current magnetic confinement fusion research and the first fusion power pilot plants. General Atomics, which operates DIII-D for the Department of Energy, announced the completion of upgrades on May 8.

Scott Forney (left), president of General Atomics Electromagnetic Systems and Mohamed Al Hammadi, managing director and CEO of ENEC. (Photo: General Atomics)

General Atomics announced last week that it will work with the Emirates Nuclear Energy Corporation to help find opportunities to support the United Arab Emirates.

Representatives from both companies signed a memorandum of understanding at the CERAWeek conference in Houston, Texas. The ENEC will work closest with General Atomics’ GA-EMS team, which develops new technologies and aims to deliver breakthrough solutions supporting environments from undersea to space.

GA’s Magnet Technologies Center. (Photo: GA)

General Atomics (GA) and Tokamak Energy Ltd. are each independently developing magnetic confinement fusion power plant concepts that would use a tokamak and high-temperature superconducting (HTS) magnets to confine and shape a plasma heated to over 100 million degrees Celsius. On May 30, they announced a memorandum of understanding to collaborate on HTS magnet technology for fusion energy and other applications.

A Framatome operator fabricates U-Mo foils at CERCA. (Photo: Framatome)

Framatome is prepared to manufacture a novel molybdenum-uranium (U-Mo) fuel to extend the life and safe operation of the Forschungsreaktor München II (FRM II) research reactor in Germany. A new fuel supply—one that uses uranium enriched to less than 20 percent U-235—means the FRM II can continue to supply neutrons to industry and the scientific community. The fuel is “Europe’s low-enriched fuel with the highest density ever realized for research reactor operations,” according to Framatome’s April 27 announcement.

A side-by-side comparison of a standard plasma configuration (at left) and the plasma created during the negative triangularity campaign at DIII-D, which was made possible by the installation of a temporary divertor region. (Image: General Atomics)

The DIII-D National Fusion Facility in San Diego, Calif., has completed a monthlong research campaign using a negative triangularity plasma configuration inside its fusion tokamak and produced initial data that “appear very encouraging,” according to an April 24 news release from General Atomics (GA), which operates the Office of Science user facility on behalf of the Department of Energy. Full experimental results on “the highest-powered negative triangularity experiments in the history of the U.S. fusion research program” are expected this summer, according to GA.

A rendering of the GA fusion pilot plant. (Image: GA)

General Atomics (GA) announced on October 20 that it has developed a steady-state, compact advanced tokamak fusion pilot plant concept “where the fusion plasma is maintained for long periods of time to maximize efficiency, reduce maintenance costs, and increase the lifetime of the facility.”

The new TRFS provides for automated adjustment of the direction of the DIII-D primary magnetic field. (Photos: GA and PPPL)

The DIII-D National Fusion Facility now boasts a unique automated system that allows for a quick reversal of the direction of its magnetic field, expanding the range of possible fusion experiments while reducing downtime. General Atomics, which operates the DIII-D for the Department of Energy’s Office of Science, announced the new Toroidal Field Reversing Switch (TFRS) on July 26.

Savannah River National Laboratory (Photo: DOE)

When the Department of Energy announced Innovation Network for Fusion Energy (INFUSE) awards earlier this month, Savannah River National Laboratory was named a recipient of two of the 18 awards. SRNL released a statement on July 19 explaining how a national lab with a long history of supporting environmental management and national security missions can lend a hand in the development of future commercial fusion power.

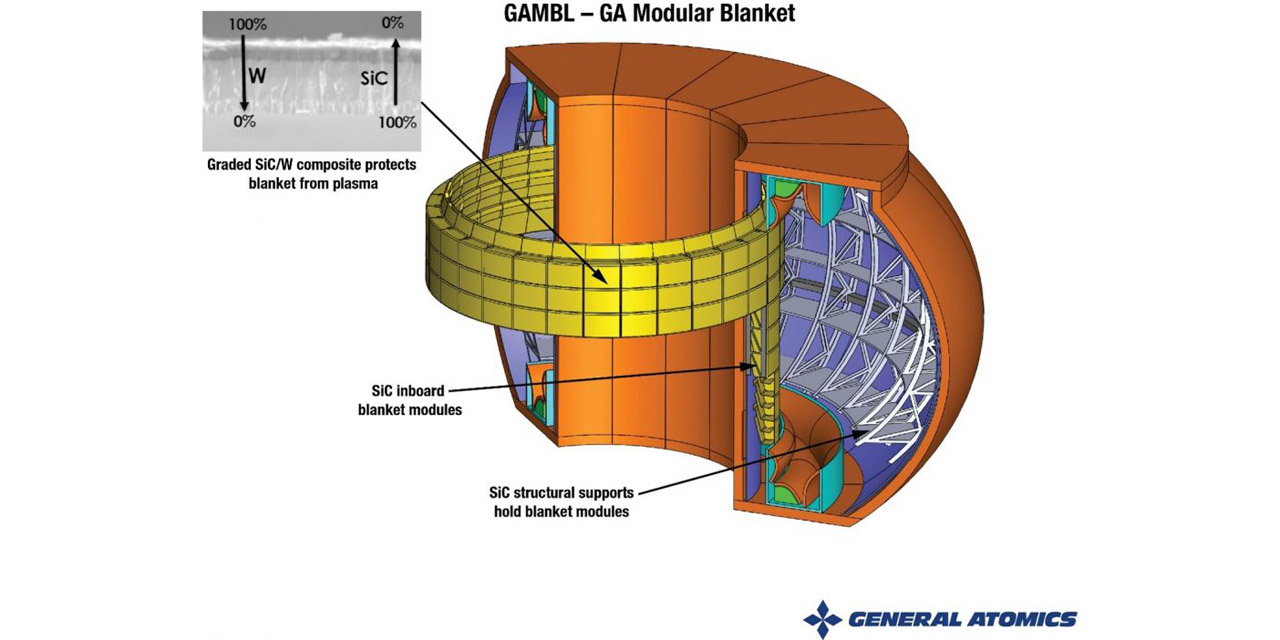

This fusion tokamak cutaway illustrates how the GAMBL concept would be incorporated into a fusion pilot plant. The SiC-tungsten composite wall provides superior heat-removal capabilities and durability, and a modular approach enables fabrication using existing technologies. (Image: GA)

Researchers at General Atomics (GA) are proposing a breeding blanket made of modular silicon carbide–based components to withstand the intense conditions in a high-power fusion power plant. The GA modular blanket (GAMBL) concept is described in an article published this month in the journal Fusion Engineering and Design, and was introduced by GA in a July 13 press release.